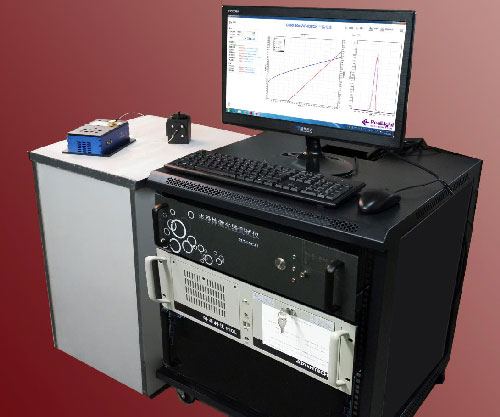

Production Process Test

The Ivy Photonics technical team takes the assembly process into consideration when designing the optical system. Avoid the human error caused by complex assembly process in the production process.

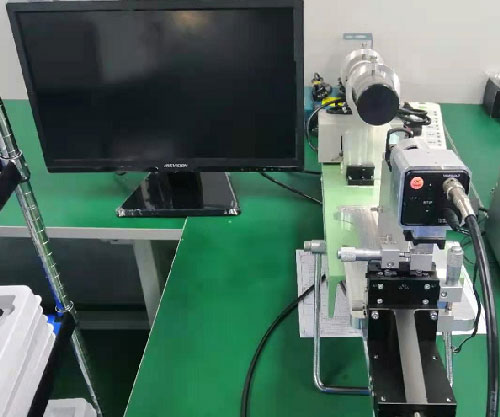

Each laser transmitting antenna is strictly adjusted by autocollimator to ensure the divergence Angle and beam directivity of the product.

IQC

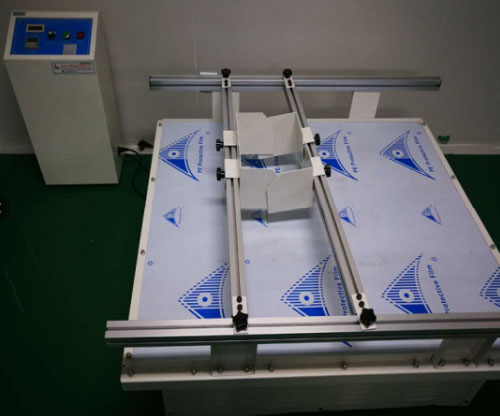

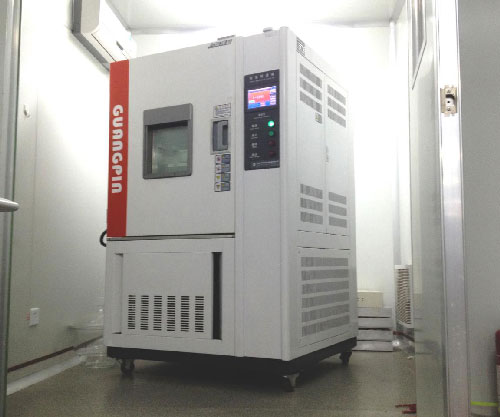

For each type of laser detection equipment, salt spray, wet heat, dipping and other experiments are carried out, which meet the requirements of GJB-150 standard. Through the use of two-dimensional imaging instrument, micrometer, dial gauge and other mechanical measuring tools, ensure the mechanical incoming material size tolerance and shape tolerance. The mechanical parts can be assembled only after adequate aging treatment and cleaning.